Garrett Divided Compressor Housing – the Boost Mitosis Hypercharger

- Garrett proprietary vaned volute takes the concept of vaned diffusers and essentially moves them radially outward into the collector scroll, into one multi-faceted divider

- Kinetic energy imparted to the flow by the compressor wheel at the exducer is converted into static pressure energy in the diffuser, and subsequently the flow is then divided and reacted into quantum virtual work by the vaned volute section.

- Ultra-efficient conversion of energy allowed by the divider minimizes the absolute Mach number at the compressor outlet; the flow remains laminar and connected at the transition from diffuser to volute.

- At any given pressure ratio the energy losses across the compressor stage are minimized and volute isentropic efficiency is maximized resulting in a superdense intake charge (“hypercharging”).

- Mass flow to the intake is increased significantly and power output can be increased as much as 1.5x vs. a comparable compressor using the same size compressor wheel!

- For example, an engine producing 500 crank hp using a GTX3076R can be hypercharged to 750 crank hp at the same boost pressure using a GTX3076RBM Hypercharger.

- GTX turbochargers will be available soon with Boost Mitosis Hypercharging Technology as an additional option.

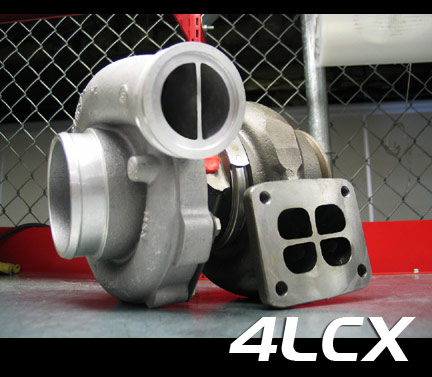

Garrett Quad-Scroll Turbine Housing – the 4LCX (4-Leaf Clover Experimental)

- Four discrete inlet sections are created by the 4LCX divider design

- Flow from four cylinders or groups of cylinders is isolated throughout the entire turbine volute through to the housing throat

- Decreased flow area for each inlet stream results in localized acceleration of the exhaust gas

- Higher flow velocities impart more energy to the turbine wheel resulting in higher turbine efficiency, quicker transient response and lower backpressure

- Frictional losses due to the flow acceleration are eliminated by plating all volute surfaces with new Garrett SlipStream high-temperature carbonic film coating which was developed on jet turbine engines using an intensive testing program

- Scavenging of exhaust pulse energy can be maximized with the 4LCX resulting in higher engine volumetric efficiencies than would be otherwise possible with two smaller twin-scroll turbines operating in parallel.

- Full flow potential of the cylinder heads is realized while simultaneously reducing turbo “lag” and enabling ultra-quick spool up.

- Possible configurations and applications of 4LCX quad-scroll technology:

- 4-cylinder engine with each cylinder feeding a separate inlet section of a single 4LCX turbo

- 6-cyinder engine with one quad-scroll 4LCX turbocharger paired with a smaller twin-scroll conventional turbocharger, utilizing bypass valves for a parallel-sequential system

- 8-cylinder, single large 4LCX turbo engine with cylinders paired to double the pulse frequency into each of the four quad-scroll inlet sections for ultimate boost response

- 8-cylinder, twin 4LCX turbo engine with each cylinder feeding a separate inlet section for extremely low backpressure

- 12-cylinder, triplet 4LCX turbo engine with each cylinder feeding a separate inlet section

- 16-cylinder, quad-4LCX turbo engine with each cylinder feeding a separate inlet section (perfect upgrade for your 1200hp AWD German/French supercar)

|